TITTLE : PROGRAM PROCESS

Below is the guide to create a program using MPLAB software.

1) Before we start, create a new folder in your c drive and rename the folder accordance to your project name/title as shown below. This folder is now become your project folder.

2) Copy the given ASM code from your project CD to your new project folder and rename it

with your own name as shown in the example below.

3) Open MPLAB IDE, go to Project Menu and Click “Project Wizard”.

4) Click “Next”

5) Select your devices. (Choose the right devices base on your project development).

6) Select your language tool suite. For assembly program development, select the setting

as shown below.

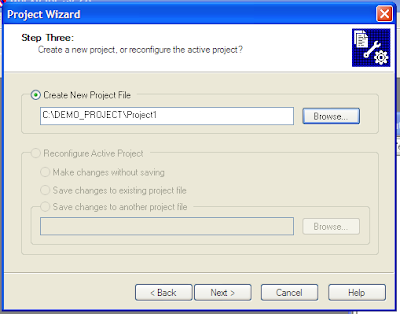

7) Browse where to locate your new MPLAB project and write a name for the project.

(recommended: select the project folder that you have created in step1.1).

8) Create a new project.

9) Select your existing assembly code/project (the assembly code in step 1.2) and click “add”

to insert to your new MPLAB project.

10) Your project wizard is now completed. Check the summary and click “Finish”.

11) Your new MPLAB project should look like the picture below.

12) To Build your new project, go to menu “Project” and click on “Build All”.

13) Click on "Absolute".

14) Below is the succeeded result after Build process.

15) Hex File generated after succeeded build.

dd.jpg)